SKIOLD TransPork - "This system saves time"

I chose SKIOLD TransPork dry feeding to limit the amount of residue and thus minimise waste.

Discover the report of Matthieu who invested in the SKIOLD Transpork, a wire distribution system for dry feed, to feed his animals in post-weaning and fattening.

Why did you invest in a dry feed distribution system?

"I took over the farm in 2009. Previously, farmers used corn and wheat with screws. I tried to do it like them for a year and then gave up. The corn was not dry enough and the chains were constantly "failing". The spirals were worn."

So Matthieu wanted to invest in a new dry feed distribution system for post-weaning and fattening. It was a well-thought-out project that would serve several purposes:

- Use the existing mixer

- Valve to valve distribution

- Reduce feed costs / formula cost

- Improve working conditions

Why did you choose the SKIOLD Transpork distribution system?

"Initially, I thought I would go with the classic pellet chain. Finally, I chose the dry cable distribution solution to limit the retention of residues and therefore waste less. I followed the advice of my dealer who highlighted the fact that there is less flour drag and less retention. In addition, the advantage would be the length that the TransPork could provide.”

The SKIOLD TransPork has the advantage of being a reliable system with a long service life that is easy to use and maintain. An argument in favour of the TransPork wire system is that the wire is sheathed, which guarantees hygiene and maintenance of wire lubrication.

How does it work?

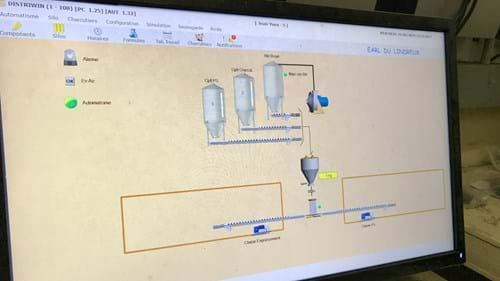

The cereals, in this case wheat, are loaded into the hopper. They are then sucked up and ground by means of a hammer mill and then expelled into the silo. They are then recovered and mixed either with the post-weaning supplement or the fattening supplement. Finally, the mixture is weighed valve by valve and then distributed. The process is controlled by the SKIOLD DistriWin software.

What did the dry feed system bring?

The SKIOLD Transpork has been operating since February 2019. This system saves time. This is mainly due to its simplicity because "it's easier than using buckets. We program the formulas in the SKIOLD DistriWin software according to age and weight and we control the monitoring of the curves."

Today, we save money on the formulas because we make them ourselves. That was the goal. We work with 2 supplements - one for post-weaning and one for fattening - and manufacture 4 feeds adapted as closely as possible to the needs: Second age, nourishers, growing and finishers. Before we used the same feed for all." Now, they adapt the feed formula to the animal's cycle. "We give the right feed at the right time." This customization makes it possible to limit waste. They are already saving money on the formula.

Do you want to know more? Contact us to find out more about our dry feeding solutions:

English

English

Danish

Danish

French

French

Swedish

Swedish

Vietnamese

Vietnamese

Spanish

Spanish

German

German

English

English