We save 100 g of feed per day per sow

But above all we're gaining in terms of quality and growth.

Read what Cyril, a 300 pig and beef cattle farmer in Aveyron, has to say. Since the end of 2021, he has been producing his own feed for his two livestock productions. He tells us about the outcome of the project and about his experience as an on-farm feed producer.

Why our own on-farm feed factory?

3 years ago, we were having problems with the animals: Diarrhoea and cannibalism. We were wondering about the quality of the feed. That's when we came up with the idea of producing our own feed on the farm.

How long did the project take?

The construction took a year to build, the time to get everything in place. We contacted Agri Tech Elevage, with whom we had worked for the liquid feed machine installed in 1993.

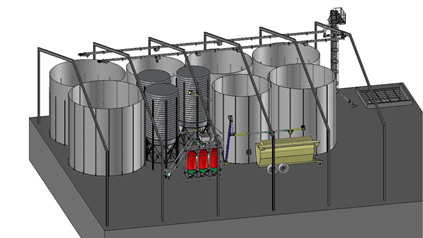

With Sylvie ALBOUY, manager of Agri Tech Elevage, we visited a number of on-farm feed productions. Then Eric MANENC, technical sales representative for SKIOLD, proposed a basic plan to us. We liked the approach! It was condensed and could develop. The idea was to have a compact on-farm feed mill so that we could add silos to the building if necessary. And the whole thing would be accessible.

What made the difference?

- The study: Listening and monitoring of the project carried out by the SKIOLD team and Agri Tech Elevage.

- The partnership: We are pleased with the finish from Agri Tech Elevage and the SKIOLD team.

- The Disc Mill. It's a good, interesting product. When we consulted the pig technicians, they favoured this system because it's easy to regulate the grain size between the different physiological stages of the animals. It's easy to switch from a pig formula to a cattle formula, so you can go from a fine feed to a coarser one. We can make any formula, whenever we want and without being there. It doesn't take long and there's very little maintenance.

How do you work with the on-farm feed mill?

With our feed mill, we produce 2,500 tonnes of feed a year to feed our animals spread over several sites.

We have a storage capacity of 1,400 tonnes of cereals (wheat, barley, triticale, sorghum and maize) and 100 tonnes of proteins (3 silos of 30-35 tonnes).

In terms of raw materials, we mainly use barley and maize for cattle, while for pork we use all the raw materials depending on their price.

In our EasyFab Pro (now FlexMix Pro) manufacturing software, we have around fifteen formulas for making feed (depending on the type of animal production and the physiological stage): 5 for cows and the rest for pigs. The software is good because you can enter as many formulas as you like. There are pending formulas and others that are programmed. It takes 30 sec. to programme the time slot. As far as our organisation for production is concerned, it's mainly me and my father who take care of it, but it doesn't take long. What does take time is the distribution of feed to the livestock at a rate of 1 h 30 per day, because we don't have a blowing system as the sites are so far apart. It takes us 1 hour to empty the trailer and 30 minutes for handling. In the summer, it takes a little longer for reception.

Is it difficult to make your own feed?

No. We work with the nutritionist to balance the rations. What I do is program the production cycles at night: For pork, I fill my 12 tonne trailer. For the cattle formula, it's easy, I leave my preparation in buffer stock in the mixer, which I then collect in a hopper.

When you start out in on-farm feed production, the most complicated part is buying raw materials, because you already have to have contacts. We wanted contacts with local farmers. Here, we're in a region with dairy sheep (Roquefort area), so it's easy to find raw materials. The fewer the middlemen, the lower the margins, and the better we can manage feed costs.

What has the feed mill brought us??

The aim was also to use the farm's own grains. They are more valuable. There are no by-products or spent grain. We know what feed we're feeding. We only use grains and oilcakes. We make the most of what we grow in the fields, and the quality of the feed shows in the animals.

We noticed it straight away! We had to regulate the feed. We're saving 100 g of feed per day per sow. That's not much per day, but over the year we're saving a lot. For fattening pigs, instead of starting at 3 months and 20 days, they start at 3 months and 10 days. We easily save 10 days. What's more, we're paid the base price and we get better value for money. The pigs are more compliant. You can see it in the eye alone. Yes, we're gaining €10 to €15 a tonne, but above all we're gaining in terms of quality and growth.

I'm talking about pigs, but calves are no different! The first year we sent out the first calves fed with our manufactured feed, the dealer said "it's night and day". Even on the price, we easily made €100 to €150 per calf. Originally, we wanted to improve the quality of our feed, but we never expected to get such a good return!

Sylvie ALBOUY, Managing Director of Agri Tech Elevage, notes that "Beyond the savings per tonne, our customers see significant differences in the animals. Moreover, we're installing more and more cattle feed mills. People often call us to change a mill, and then Sylvain tells them about the on-farm feed mill for cattle. And they say 'why didn't I do that 10 years ago?

Do you have any advice for other farmers who want to invest in on-farm feed production?

Get a dust collector. We remove most dust to limit mycotoxins in pigs.

To have a system that can be expanded. Today, we have beef production, but maybe one day we'll have a new unit with poultry or we'll expand the pig farm. We don't know what might happen. So we have to think about how we can evolve. Here, we've decided to keep space to integrate other silos to have enough storage. And maybe we'll have to upgrade the equipment. You have to think about the future.

An installation carried out in collaboration with SKIOLD France dealer Agri Tech Elevage

Do you want to make your own feed? Contact us to find out more about our customisable feed milling solutions:

CONTACT US FOR FURTHER INFORMATION

Farm information :

- EARL Du Mousse, Brasc

- 3 partners

- Animal production :

- Pigs: 300 sows

- Beef cattle: 80 Limousin cows

- UAA: 165 Ha (including 70 Ha of cereals)

- Production of 2,500 tonnes of feed per year

- SKIOLD MecaMix on-farm feed mill commissioned in December 2021

English

English

Danish

Danish

French

French

Swedish

Swedish

Vietnamese

Vietnamese

Spanish

Spanish

German

German

English

English